Anti-Foaming Agents Market opportunities expand with growing applications in pharmaceutical and biotechnology manufacturing processes

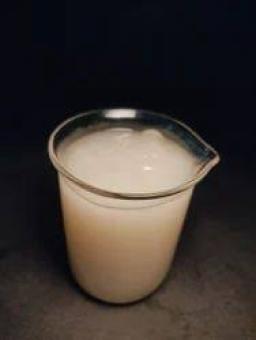

Anti-Foaming Agents Market opportunities expand with growing applications in pharmaceutical and biotechnology manufacturing processes, creating strong potential for manufacturers worldwide. Foam often forms during fermentation, chemical reactions, or liquid mixing in bioprocessing, which can compromise product quality and production efficiency. Uncontrolled foam leads to contamination, higher cleaning costs, and longer processing times. Anti-foaming agents play a critical role by reducing foam generation, ensuring reliable operations, and improving yields. As the pharmaceutical industry grows due to rising demand for vaccines, biologics, and therapeutic drugs, reliance on foam-control agents is expected to increase significantly.

Foam Challenges in Pharma and Biotech

Foam develops during drug fermentation, enzyme production, and protein synthesis. If not controlled, foam can lead to vessel overflows, blocked sensors, and disrupted oxygen transfer in fermenters. This impacts both the quality and quantity of end products. By using anti-foaming agents, companies avoid these risks, maintaining production consistency and safeguarding product purity.

Expanding Applications in Pharmaceutical Manufacturing

Fermentation-based Drug Production : Antibiotics, vaccines, and biologics rely heavily on fermentation processes, where foam-control solutions are essential.

Protein and Enzyme Production : Foam management improves efficiency during protein expression and enzyme manufacturing, ensuring higher yields.

Drug Formulation and Mixing : During liquid drug formulation, anti-foaming agents stabilize mixtures and prevent spillage or contamination.

These applications highlight how anti-foaming agents contribute directly to safer and more efficient drug manufacturing.

Biotechnology Industry and Foam Control

The biotechnology industry uses complex fermentation techniques to produce biofuels, industrial enzymes, and bio-based chemicals. Foam buildup can disrupt large-scale bioreactors, causing safety hazards and efficiency losses. Anti-foaming agents ensure bioprocesses remain consistent and scalable, particularly as bio-based alternatives gain momentum in global markets.

Drivers of Market Growth

Rising Demand for Biopharmaceuticals : Increased need for advanced drugs, including monoclonal antibodies and vaccines, supports the adoption of anti-foaming solutions.

Global Expansion of Biotech Industry : Emerging economies are investing in biomanufacturing facilities, further boosting foam-control applications.

Stringent Quality Standards : Pharmaceutical and biotech industries require high-purity operations, making specialized anti-foaming agents indispensable.

Regulatory and Safety Considerations

Pharmaceutical and biotechnology applications demand compliance with strict regulatory guidelines. Anti-foaming agents must be non-toxic, biocompatible, and suitable for sensitive applications. This ensures patient safety while maintaining production efficiency. Manufacturers are investing in developing medical-grade, safe, and sustainable foam-control solutions to meet global requirements.

Technological Innovations in Anti-Foaming Agents

Recent advancements are shaping the industry:

Silicone-based pharma-grade agents with enhanced effectiveness and low toxicity.

Non-silicone alternatives using plant oils for clean-label drug processing.

Specialized emulsions improving dispersibility in sterile environments.

These innovations improve the balance between effectiveness, safety, and sustainability in pharmaceutical and biotechnology applications.

Regional Insights

North America : Strong demand driven by advanced pharmaceutical manufacturing and biologics production.

Europe : Adoption fueled by strict regulatory frameworks and significant biotech investments.

Asia-Pacific : Fastest-growing region, with India and China emerging as major hubs for drug and vaccine production.

Latin America and Africa : Gradual adoption as healthcare infrastructure and drug manufacturing expand.

Challenges in Adoption

Despite growing demand, certain barriers exist:

High costs of specialized medical-grade anti-foaming agents.

Complexity in developing non-toxic and fully biocompatible formulations.

Need for extensive testing before regulatory approvals are granted.

Future Outlook

The pharmaceutical and biotechnology sectors will continue to drive the demand for anti-foaming agents. With rising investments in drug research, vaccine development, and bio-based manufacturing, foam-control solutions will become increasingly important. Innovation, regulatory compliance, and sustainability will shape the future growth of this segment.

Conclusion

The anti-foaming agents market is seeing new opportunities expand with growing applications in pharmaceutical and biotechnology manufacturing. From fermentation to formulation, these agents enhance efficiency, safety, and quality. As global healthcare and biotech industries advance, the need for innovative and safe foam-control solutions will continue to strengthen.