Photomask Inspection Market Growth Driven by Semiconductor Advancements and Precision Manufacturing Requirements

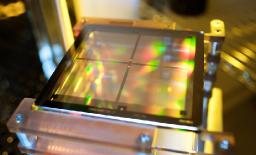

The photomask inspection market is witnessing substantial growth, supported by rapid innovations in semiconductor manufacturing, growing global chip demand, and the rising need for ultra-precise patterning at smaller process nodes. As semiconductor devices become more advanced and miniaturized, the tolerance for errors in photomask creation shrinks dramatically. Photomask inspection plays a vital role in identifying and eliminating defects that can affect circuit pattern transfer onto wafers, making it an indispensable component of the semiconductor production process.

One of the key factors driving the growth of this market is the evolution toward advanced semiconductor nodes , such as 7nm, 5nm, and 3nm technologies. As transistors are packed more densely onto chips, even the slightest imperfection in a photomask can lead to critical faults or lower yields. This trend is driving the demand for high-resolution, accurate, and automated photomask inspection tools that can detect the smallest defects in complex layouts. Manufacturers are now investing more in state-of-the-art inspection systems to ensure first-pass success, improve throughput, and reduce costly rework.

The rise of extreme ultraviolet (EUV) lithography is another major catalyst fueling photomask inspection market growth. EUV technology allows for finer patterning with fewer masks, but it also introduces new challenges in defect detection due to its shorter wavelength and complex mask structures. EUV photomasks are highly sensitive to particle contamination, reflectivity issues, and phase defects. To address these challenges, semiconductor fabs are deploying EUV-compatible actinic inspection tools, which simulate actual lithography conditions and deliver superior defect detection performance. As EUV adoption accelerates globally, demand for advanced photomask inspection solutions is increasing in parallel.

A significant contributor to market expansion is the integration of artificial intelligence (AI) and machine learning into inspection systems. Traditional inspection methods rely on rule-based algorithms, which can produce false positives or miss subtle anomalies. AI-powered systems, however, can analyze large volumes of inspection data, learn from defect trends, and improve detection accuracy over time. These systems enable fabs to optimize inspection cycles, reduce manual intervention, and enhance defect classification. As semiconductor manufacturing becomes more data-centric and intelligent, the adoption of AI-driven inspection tools is expanding rapidly.

The global surge in semiconductor demand across industries like consumer electronics, automotive, telecommunications, and industrial automation is also driving photomask inspection market growth. With chips powering everything from smartphones to electric vehicles and smart home devices, ensuring chip reliability has become a top priority. Photomask inspection helps achieve this by detecting and preventing defects early in the production cycle. As manufacturers scale up production to meet soaring demand, investments in inspection infrastructure are increasing accordingly.

Additionally, geographic expansion of semiconductor fabrication facilities is playing a crucial role in market growth. Countries such as the United States, China, South Korea, and those in the European Union are investing heavily in local chip production capabilities through subsidies, joint ventures, and technology partnerships. Each new fab requires a full set of advanced inspection tools, including those for photomask validation. The localization of semiconductor production is creating new opportunities for inspection tool vendors to serve a more diversified global customer base.

Advanced chip packaging and 3D architectures are also contributing to photomask inspection market growth. As manufacturers explore heterogeneous integration, system-in-package (SiP) designs, and 3D stacking, inspection systems must adapt to more complex geometries and tighter tolerances. Photomasks used in these advanced designs require multi-dimensional verification to ensure alignment and pattern fidelity across different layers and components. This trend is pushing tool makers to enhance their systems with better resolution, alignment capabilities, and multilayer inspection features.

Furthermore, the push for higher yield and lower production costs has made photomask inspection a strategic priority in semiconductor fabs. Yield loss due to undetected mask defects can result in massive financial setbacks, especially when producing at advanced nodes. Inspection tools that enable early defect detection and accurate classification contribute directly to improved yield and cost efficiency. As fabs seek to maximize productivity and minimize waste, demand for advanced inspection systems continues to grow.

The competitive landscape is also encouraging innovation and market expansion. Established players are enhancing their product portfolios with faster, more intelligent, and scalable solutions, while new entrants are introducing agile, AI-enabled platforms tailored to specific inspection challenges. This competitive pressure is accelerating the development of next-generation inspection systems and increasing availability across different price points and performance tiers.

In conclusion, the photomask inspection market is experiencing strong and sustained growth, driven by advancements in semiconductor technology, increased chip production, and the rising importance of defect-free manufacturing. From AI integration to EUV compatibility and global fab expansion, multiple factors are converging to elevate the role of photomask inspection in modern chipmaking. As the semiconductor industry continues to evolve, the demand for precise, intelligent, and scalable inspection solutions is set to grow even further.