Flexible lid stock packaging refers to thin, versatile films used to seal a wide range of containers, primarily in the food, pharmaceutical, and personal care industries. These films serve as a protective barrier that maintains product freshness and extends shelf life by preventing contamination. They are typically made from materials such as aluminum foil, polyester, or laminated plastics and are heat-sealed onto containers for secure closure. Common materials include polyethylene (PE), polypropylene (PP), aluminum foil, and occasionally paper or non-woven substrates—selected for their flexibility, strength, and excellent sealing properties.

Flexible Lid Stock Packaging Market Expansion Strategies and Forecast 2032

According to Fortune Business Insights, The global Flexible Lid Stock Packaging Market is witnessing strong growth, driven by increasing demand for convenient, lightweight, and sustainable packaging solutions across the food, beverage, and healthcare sectors. According to Fortune Business Insights, the market was valued at USD 2.59 billion in 2024 and is projected to grow from USD 2.74 billion in 2025 to USD 4.09 billion by 2032, exhibiting a CAGR of 6.05% during the forecast period (2025–2032).

Flexible lid stock packaging plays a crucial role in preserving product freshness, extending shelf life, and ensuring tamper-evident sealing — all of which are essential in modern packaging applications.

Request a FREE Sample Copy: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/flexible-lid-stock-packaging-market-109395

Key Market Drivers

1. Rising Demand in Food & Beverage Sector

The growing consumption of packaged and ready-to-eat foods is one of the primary factors driving market growth. Flexible lid stock packaging provides excellent sealing and barrier properties against oxygen and moisture, making it ideal for packaging dairy products, beverages, and frozen foods.

2. Increasing Adoption of Sustainable Packaging

Manufacturers are focusing on recyclable and eco-friendly materials to align with global sustainability goals. The transition toward mono-material lid stocks and recyclable laminates is enhancing the market’s growth potential.

3. Expansion in Pharmaceutical and Healthcare Applications

Flexible lid stock packaging is gaining popularity in the pharmaceutical industry due to its superior sealing performance, light protection, and contamination resistance — particularly in blister packs and sterile medical packaging.

4. Technological Advancements in Packaging Materials

Innovations in film technologies, barrier coatings, and printing techniques are improving the performance and aesthetics of flexible lid stock packaging, helping brands stand out in competitive retail environments.

Market Segmentation

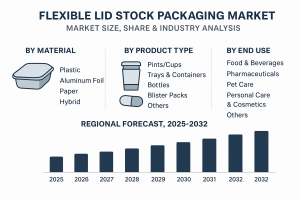

By Material Type

Plastic (PE, PET, PP, etc.) – Dominates the market due to cost-effectiveness, durability, and versatility.

Aluminum Foil – Preferred for high-barrier applications in food and pharma packaging.

Paper and Others – Growing steadily with the rise of sustainable and recyclable options.

By Application

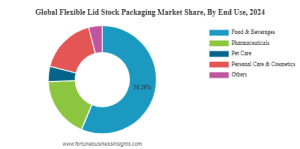

Food & Beverage – Largest segment, driven by the packaging needs of dairy products, ready meals, and snacks.

Pharmaceuticals – Increasing adoption in blister packs and medical trays.

Personal Care & Others – Expanding use in cosmetic containers and hygiene product packaging.

By Region

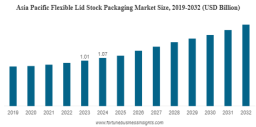

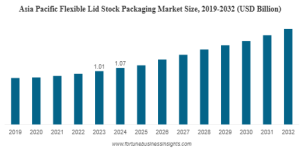

Asia Pacific dominated the global market with a 41.02% share in 2024 , attributed to high consumption of packaged foods, growing retail infrastructure, and rising disposable incomes in countries like China and India.

North America and Europe continue to see steady growth, supported by innovation and stringent environmental regulations encouraging recyclable packaging solutions.

Latin America and the Middle East & Africa are emerging as high-potential markets due to expanding food processing and pharmaceutical industries.

List of Key Flexible Lid Stock Packaging Companies Profiled

- Tekni-Plex, Inc. (U.S.)

- Huhtamaki (Finland)

- Constantia Flexible (Austria)

- Sealed Air (U.S.)

- Mas Flexible (Turkey)

- Berry Global (U.S.)

- Amcor plc (Switzerland)

- Elite Packaging (U.S.)

- Safepack (India)

- DuPont (U.S.)

- Wipak (Canada)

- KM Packaging Services Ltd. (U.K.)

These companies are focusing on product innovation, sustainability-driven packaging solutions, and regional expansion to strengthen their global presence.

Recent Industry Developments

Leading packaging manufacturers are investing in recyclable and bio-based lid stock materials to meet growing consumer demand for eco-friendly packaging.

Collaborations and acquisitions are increasing across the sector to enhance technological capabilities and expand product portfolios.

Automation and digital printing technologies are being integrated to improve production efficiency and customization in packaging.

Information Source: https://www.fortunebusinessinsights.com/flexible-lid-stock-packaging-market-109395

The Flexible Lid Stock Packaging Market is expected to continue its robust growth through 2032, driven by sustainability trends, material innovations, and expansion of packaged food and pharmaceutical industries. The push for recyclable and lightweight packaging will create new opportunities for manufacturers, while the Asia Pacific region remains the most promising market for future investments.

KEY INDUSTRY DEVELOPMENTS

- In July 2025, Greiner Packaging launched Click On and Click In sealing lids, which are mono-material packaging solutions aimed at improving sustainability and convenience by removing the necessity for aluminum foil while guaranteeing resealability and recyclability for a range of products. Sealing lids operate on a two-component principle: a cup and a lid. This enables the intentional exclusion of a third component such as aluminum foil. The benefit is that both elements can be constructed from the same material, such as PP, PET, or r-PET.