Diffractive Optical Elements Market Shifts Driven by Technological Innovations and Changing Industry Demands Globally

The diffractive optical elements market is experiencing significant shifts as technological progress and evolving industry requirements reshape the way these optical components are designed, manufactured, and deployed. Diffractive optical elements (DOEs) have long been valued for their ability to manipulate light with high precision in compact forms, but recent developments are transforming their market dynamics, creating new opportunities and challenges. Understanding these shifts is critical for stakeholders aiming to capitalize on the evolving DOE landscape.

One of the most prominent shifts in the DOE market is the transition from traditional fabrication methods to advanced, scalable manufacturing technologies . Historically, DOEs were fabricated using complex, time-intensive processes like electron beam lithography and laser writing, which limited production volume and kept costs high. However, the market is shifting towards adopting mass-production techniques such as nanoimprint lithography and roll-to-roll processing. These newer methods enable faster throughput and reduce manufacturing expenses, making DOEs more accessible for a wider range of applications. This shift is crucial in meeting the rising demand from high-volume sectors like consumer electronics and telecommunications.

Another key market shift is the broadening of application areas beyond conventional industries . While DOEs have traditionally found strong use in laser systems, optical communications, and scientific instruments, emerging sectors are increasingly adopting these elements. For example, the healthcare industry is integrating DOEs into advanced imaging modalities and minimally invasive surgical devices, capitalizing on their precision and compactness. Similarly, the automotive sector is utilizing DOEs in lidar sensors and driver-assistance systems, which require sophisticated beam shaping capabilities. This diversification into new verticals reflects a market shift towards multifunctionality and cross-industry innovation.

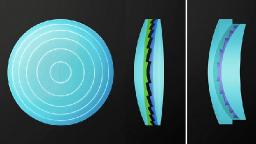

The rising emphasis on miniaturization and integration within optical systems is another notable trend shaping the DOE market. With the surge in demand for portable, wearable, and compact devices, manufacturers are shifting focus towards designing DOEs that enable smaller, lighter, and more efficient optical assemblies. This change drives innovation in microfabrication techniques and materials to produce thinner and more robust elements. It also encourages the development of hybrid optical solutions that combine diffractive and refractive components to optimize performance while reducing size and weight. This shift towards miniaturization is transforming product design strategies across multiple industries.

Material innovations are also driving significant shifts in the DOE market. Traditional DOEs often relied on glass or semiconductor substrates, but recent advancements are enabling the use of novel materials such as polymers, photoresists, and meta-materials. These materials offer advantages including flexibility, cost reduction, and enhanced optical properties like higher diffraction efficiency and broader wavelength compatibility. The shift toward alternative substrates expands DOE applicability to flexible electronics, wearable sensors, and even environmentally friendly optical devices. Material science breakthroughs continue to reshape market offerings and product capabilities.

The integration of artificial intelligence (AI) and computational design techniques marks a transformative shift in how DOEs are conceptualized and optimized. Instead of relying solely on conventional trial-and-error design methods, engineers increasingly use AI-powered algorithms to generate DOE patterns that achieve highly specialized light manipulation with minimal loss. This computational approach shortens design cycles, improves device performance, and enables customized solutions tailored to specific application needs. The adoption of AI in DOE development is accelerating innovation and pushing the boundaries of what these optical elements can achieve.

Market demand is also shifting in response to growing sustainability and environmental concerns . There is increasing pressure on manufacturers to adopt eco-friendly production processes and use recyclable or biodegradable materials for DOE fabrication. Regulatory frameworks in several regions are pushing for reduced chemical waste and lower energy consumption during manufacturing. This shift towards sustainable practices is not only driven by compliance but also by consumer preference for green technologies. Companies investing in environmentally responsible manufacturing are gaining competitive advantages in the evolving market.

The competitive landscape of the DOE market is undergoing change as well, with emerging players entering alongside established industry leaders . Startups and smaller companies are introducing innovative designs and niche applications, while larger corporations focus on scaling production and expanding product portfolios. This influx of new participants is driving market consolidation and collaboration, as companies seek strategic partnerships to enhance R&D capabilities and market reach. The competitive shift encourages continuous technological progress and diversified offerings for end-users.

Geographically, the DOE market is witnessing shifts in regional dominance and investment focus . While North America and Europe have traditionally led in DOE technology development, Asia-Pacific is rapidly gaining ground due to government initiatives, increased R&D funding, and growing demand from electronics and telecommunications sectors. Countries like China, Japan, and South Korea are becoming key manufacturing hubs, leveraging cost advantages and skilled labor. This regional shift influences global supply chains and accelerates innovation through localized expertise and resources.

Finally, consumer expectations are influencing the DOE market shift toward higher performance, reliability, and customization . End-users demand optical components that not only meet stringent technical requirements but also integrate seamlessly into complex systems. This has led to a focus on improving durability, thermal stability, and wavelength versatility of DOEs. Additionally, customization options are becoming more important, enabling manufacturers to deliver application-specific solutions quickly. This customer-centric shift encourages agile development and enhances market responsiveness.

In conclusion, the diffractive optical elements market is undergoing multifaceted shifts driven by advances in manufacturing, expanding applications, miniaturization, material innovation, AI integration, sustainability, changing competition, regional dynamics, and evolving customer needs. These changes collectively redefine the DOE industry landscape, offering exciting growth opportunities and demanding adaptive strategies from market players. Embracing these shifts will be critical for companies aiming to succeed in this fast-evolving optical components market.