Carbon Fiber Reinforced Plastics Market Trends, Growth & Forecast 2032

Carbon Fiber Reinforced Plastics (CFRPs) have become a cornerstone material across high-performance industries due to their superior strength-to-weight ratio, exceptional rigidity, and resistance to corrosion and fatigue. Composed of carbon fibers embedded within a polymer matrix, CFRPs are increasingly used in industries such as aerospace, automotive, wind energy, sports equipment, and construction, where both strength and lightweight characteristics are essential.

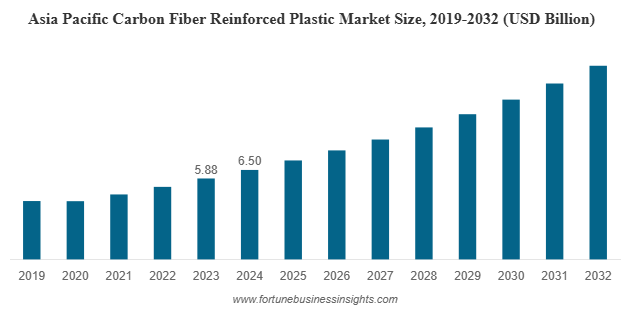

In 2024, the global carbon fiber reinforced plastic (CFRP) market was valued at USD 18.92 billion. It is expected to rise to USD 20.72 billion in 2025 and further reach USD 38.02 billion by 2032, registering a CAGR of 9.1% over the forecast period. Asia Pacific led the market with a dominant 34.36% share in 2024.

Market Drivers

The rising adoption of CFRP materials is primarily driven by growing demand for lightweight, fuel-efficient components in the transportation and energy sectors. In aerospace, CFRPs are used extensively in fuselage panels, wings, and other structural parts to reduce aircraft weight and improve fuel economy. The automotive sector, particularly the electric vehicle (EV) segment, is integrating CFRP into body frames, battery housings, and interior components to extend vehicle range and improve performance.

Wind energy is another significant growth area, where CFRP is utilized in turbine blades due to its durability and ability to withstand extreme environmental stress while keeping structural weight low. In civil construction, CFRP is increasingly used for bridge reinforcement, seismic retrofitting, and advanced façade applications.

List Of Key Market Players Profiled In The Report

- Hexcel Corporation (U.S.)

- TORAY INDUSTRIES, INC. (Japan)

- SGL Carbon (Germany)

- Mitsubishi Chemical Group Corporation. (Japan)

- TEIJIN LIMITED. (Japan)

- Solvay (Belgium)

- Formosa Plastics (Taiwan)

- DowAksa (Turkey)

- Zhongfu Carbon Fiber Core Cable Technology Co., Ltd (China)

- HS HYOSUNG ADVANCED MATERIALS (South Korea)

Material Trends and Segmentation

- The CFRP market can be segmented by raw material, resin type, form, application, and region. Based on raw materials, PAN-based carbon fibers dominate the market due to their superior mechanical properties, making them ideal for high-performance applications. Pitch-based fibers are used in specific sectors requiring higher thermal and electrical conductivity.

- In terms of resin, thermosetting resins, particularly epoxy, hold the largest share, known for their excellent bonding strength and thermal stability. However, thermoplastic CFRPs are gaining traction due to faster manufacturing times, recyclability, and better impact resistance.

- Form-wise, CFRP is available in different types including prepregs (pre-impregnated fibers), woven fabrics, and chopped fibers, each suited to specific applications ranging from aerospace to sporting goods. By application, aerospace and defense remain the largest consumers, followed by automotive, wind energy, construction, and consumer electronics.

Regional Insights

- Asia Pacific

The Asia Pacific region is the largest and fastest-growing market, led by countries such as China, Japan, and South Korea. The region’s dominance is supported by a robust manufacturing base, growing renewable energy capacity, and rising demand for lightweight materials in transportation and electronics.

- North America

North America follows closely, with strong contributions from the U.S., which is a major hub for aerospace, defense, and EV manufacturing. Technological advancements and high investments in innovation are driving adoption across various sectors.

- Europe

Europe holds a significant market share with strong support from automotive manufacturers and renewable energy developers. The region is home to several key players in the wind energy and luxury automotive sectors, both of which heavily rely on CFRP.

- Rest of the World

Regions such as Latin America, the Middle East, and Africa are in the early stages of CFRP adoption but show potential due to infrastructure development, urbanization, and rising investment in energy and transportation.

Read More : https://www.fortunebusinessinsights.com/carbon-fiber-reinforced-plastics-cfrps-market-110101

Key Industry Developments

- March 2025: Hexcel and FIDAMC have partnered to advance composite materials for aerospace and industrial applications. Their collaboration focuses on developing innovative manufacturing processes to enhance lightweight, high performance composites. This partnership aims to improve efficiency and sustainability in composite production.

- November 2024: Toray advanced composites expanded its thermoplastic composites portfolio by acquiring Gordon Plastics assets in Colorado. The new 47,000 sq.ft facility enhances R&D and scalable production of high-performance composite tapes for aerospace, sports, oil & gas, and industrial markets.

Challenges and Restraints

Despite its advantages, CFRP adoption faces several barriers. The high cost of production and raw materials remains a significant challenge, especially for cost-sensitive applications. In addition, recycling and disposal of thermosetting composites are technically difficult, limiting their environmental sustainability.

Manufacturing CFRPs also requires specialized skills and equipment, which increases production time and cost. Further, limited availability of carbon fiber manufacturing infrastructure in some regions restricts market growth.

Future Outlook and Opportunities

The CFRP market is poised for significant expansion as industries shift toward sustainability, efficiency, and innovation. The rise of electric mobility, the global push for renewable energy, and advancements in construction and infrastructure development are expected to fuel demand.

Emerging innovations such as automated fiber placement, recyclable thermoplastic composites, and low-cost manufacturing technologies will help overcome current challenges and enhance adoption. Governments and private players are investing heavily in R&D to improve recycling technologies and to develop cost-effective production methods.

Furthermore, with CFRP applications expanding into robotics, medical devices, marine structures, and consumer electronics, the material’s versatility continues to be a key growth driver.

The global carbon fiber reinforced plastic (CFRP) market is on a dynamic growth path, driven by increasing demand for lightweight and high-strength materials across various sectors. While the market faces challenges such as high costs and limited recyclability, ongoing innovations and investments are likely to address these constraints. With robust growth expected across Asia Pacific, North America, and Europe, CFRPs are set to become even more integral to modern industrial applications in the years to come.