Protective Clothing Market Trends, Growth & Forecast 2032

The global protective clothing market continues to expand steadily, reflecting an increasing global emphasis on occupational safety, regulatory mandates, and technological advances in material science. Protective garments safeguard workers against diverse hazards—including chemical exposure, thermal and flame risks, mechanical injury, biological contamination, and radiation—across sectors such as oil & gas, healthcare, construction, manufacturing, and firefighting.

The global protective clothing market was valued at USD 12.48 billion in 2019 and is anticipated to reach USD 34.31 billion by 2027, growing at a CAGR of 14% over the forecast period. In 2019, North America led the global market, accounting for a 37.4% share, with a regional market size of USD 4.34 billion in 2018. The U.S. market alone is expected to rise to USD 10.45 billion by 2027, driven by stricter workplace safety regulations and increasing demand from the healthcare sector.

Key Market Drivers

- Regulatory Requirements & Safety Enforcement

Stringent health and safety regulations worldwide have made protective clothing a legal requirement in many industries. Organizations operating in high-risk environments—such as chemical processing, mining, construction, or healthcare—are obligated to provide protective garments tailored to specific hazards, prompted by both legal frameworks and liability considerations.

- Industrial Expansion & Workplace Exposure

Industrial sectors with heightened exposure to hazards—like oil & gas, pharmaceuticals, heavy industry, firefighting, and mining—are fueling demand for specialized protective gear. Emerging economies, especially in Asia-Pacific and Latin America, are rapidly developing infrastructure, manufacturing, and urban projects that further elevate protective clothing requirements.

- Innovations in Material & Design

Protective garments are increasingly incorporating advanced materials like aramid fibers, PBI blends, coated synthetics, and breathable composites. Innovations include flame-retardant textiles, chemical-resistant coatings, anti-static fabrics, and wearable sensors for environmental or physiological monitoring. Ergonomic designs that provide greater comfort, flexibility, and fit are becoming essential for longer wear durations.

- Rising Demand from Healthcare & Life Sciences

The healthcare and pharmaceutical industries have become significant adopters of protective clothing, focusing on infection control and biohazard protection. Emergency situations and global health crises reinforce the need for specialized attire such as lab suits, gowns, and respirator-integrated outerwear.

List of Top Protective Clothing Companies:

- Honeywell International Inc. (U.S.)

- Lakeland Inc. (U.S.)

- L. Gore & Associates, Inc. (U.S.)

- PBI Performance Products, Inc. (U.S.)

- TenCate Protective Fabrics (U.S.)

- Kimberly-Clark Corporation (U.S.)

- Ansell Microgard Ltd. (U.K.)

- DuPont (U.S.)

- Bennett Safetywear Ltd. (U.K.)

- TEIJIN LIMITED (Japan)

Market Segmentation

By Material Type

- Aramid & Blended Fabrics: Ideal for extreme heat, fire, and chemical resistance.

- High-Performance Fibers (e.g., PBI): Provide protection in severe environments like firefighting or petrochemical operations.

- Polyolefin & Polyester Blends: Offer general protection in industrial settings.

- Cotton & Laminated Textiles: Cost-effective options for lightweight protection or use in controlled environments.

By Application

- Thermal/Flame Protection

- Chemical Protection

- Mechanical Protection (Cuts, Abrasion, Impacts)

- Biological & Radiological Protection

- Cleanroom Apparel

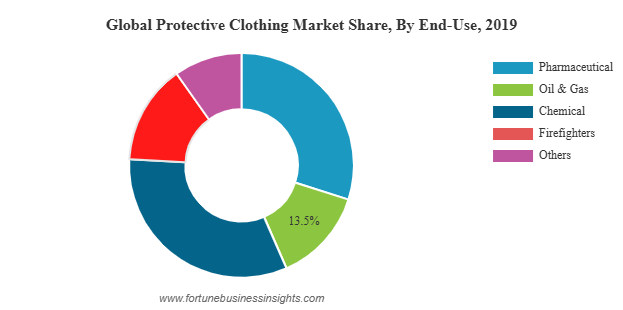

By End‑Use Industry

- Oil & Gas, Chemicals & Petrochemicals

- Construction & Industrial Manufacturing

- Pharmaceuticals & Healthcare

- Firefighting & Emergency Services

- Law Enforcement & Defense

- Energy, Mining & Utilities

By Distribution Channel

Sales occur via trade distributors, direct procurement contracts (especially with large enterprises or government bodies), industrial safety suppliers, and increasingly, through digital channels.

Read More : https://www.fortunebusinessinsights.com/protective-clothing-market-102707

Regional Breakdown

- North America

Leading global revenue share, supported by mature safety standards, rigorous enforcement, strong industry presence, and high adoption of wearable technologies—such as sensor-integrated suits and fatigue monitoring.

- Asia‑Pacific

Fastest-growing region, driven by industrial expansion, urban development, and increasing occupational safety awareness. Countries like China, India, and Southeast Asia exhibit surging demand across manufacturing, oil, construction, and mining.

- Europe

Stable growth led by strict safety regulations, sustainable material mandates, and a focus on ergonomic design and performance textiles. European markets show rapid adoption of reusable and recyclable protective garments.

- Latin America, Middle East & Africa

These emerging regions show rising demand due to growing infrastructure investment, investments in oil & gas and utilities, and gradually improving workplace safety frameworks.

Challenges & Restraints

- High Production Costs

Specialized materials and complex certifications raise production expenses, which can limit adoption, especially among smaller businesses in cost-sensitive regions.

- Technical Complexity & Expertise

Tailoring protective garments to specific hazard conditions requires specialized design capabilities. Lack of technical resources in some regions can delay adoption.

- Supply Chain & Raw Material Volatility

Fluctuating prices of high-performance fibers and disruptions in sourcing can impact product pricing and availability.

- Recycling & Sustainability Hurdles

Durable protective materials are often not recyclable in conventional systems. Designing garments that can be sanitized, reused, or recycled presents logistical challenges.

Key Industry Developments:

- In March 2020 - Protective Industrial Products (PIP) announced the expansion of salesforce in Latin America for industrial protective products. This will help the company in expanding the supply chain and support the growing demand of customers through better distribution network to the local market.

- In February 2019 - Protective Industrial Products Inc. acquired West Chester Protective Gear. The company specializes in the manufacturing of protective apparel for industrial purposes. This acquisition will help in strengthening product portfolio and complement the customer base.

Key Innovations & Market Opportunities

- Smart & Connected Protective Clothing

Integration of sensors into garments enables detection of exposure to chemicals, temperature stress, fatigue, or hazardous conditions. This real-time monitoring enhances safety and operational responsiveness.

- Eco-Friendly & Reusable Materials

Demand is rising for protective gear made from reusable or biodegradable fabrics. Particularly in healthcare and industrial sectors, initiatives support garments that meet hygiene and safety standards yet reduce environmental impact.

- Enhanced Ergonomics & Adaptive Designs

Flexible layering systems, breathable fabrics, and adjustable fittings are improving wearer comfort without compromising safety—especially important for long-duration use.

- Sectoral Expansion

Applications are expanding into robotics, aerospace, utilities, and off-shore operations where combined technical fabrics and wearable electronics provide multi-level protection.

Strategic Outlook

The global protective clothing market is poised for consistent growth over the next decade. Demand is being shaped by tightening regulatory requirements, increasing exposure to hazardous work environments, and technological innovation in textiles. Smart and sensor-embedded garments, sustainable fabric alternatives, and advanced visibility and protection standards offer critical growth pathways.

Providers that invest in R&D, sustainable manufacturing, and ergonomic integration—while partnering with industries to tailor solutions—will likely lead future market development. As industries continue to globalize and safety standards evolve, protective clothing remains an essential investment in mitigating risk and safeguarding human resources worldwide.