Thermoplastic Elastomer (TPE) Market Demand, Drivers & Global Growth, Forecast 2032

The global thermoplastic elastomer (TPE) market was valued at USD 26,856.8 million in 2019 and is expected to grow to USD 39,424.6 million by 2027, registering a CAGR of 5.7% during the forecast period. In 2019, Asia Pacific led the market, holding a dominant 52.97% share. In the United States, the TPE market is anticipated to reach USD 6,045 million by 2027, fueled by rising demand for lightweight and durable materials across automotive and consumer goods sectors.

Market Size and Growth Outlook

The global Thermoplastic Elastomer (TPE) market is on a strong growth trajectory, driven by increasing demand from automotive, construction, medical, footwear, electronics, and other key industries. TPEs are unique materials that combine the elasticity of rubber with the processability of plastics, offering flexibility, durability, and recyclability. This combination of properties makes them an ideal choice for a wide range of applications, particularly in industries looking for high-performance and sustainable material solutions.

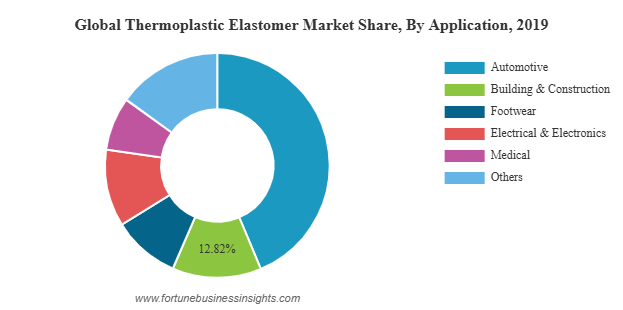

The automotive industry remains the largest consumer of TPEs, using them in products such as seals, gaskets, bumpers, interior components, and weatherproofing materials. Construction, electronics, medical devices, and consumer goods industries are also increasingly adopting TPEs due to their superior performance characteristics.

List Of Key Companies Profiled In Thermoplastic Elastomer Market:

- Arkema SA (Colombes, France)

- Covestro AG (Leverkusen, Germany)

- Evonik Industries AG (Essen, Germany)

- Teknor APEX Company (Rhode Island, U.S.)

- BASF SE (Ludwigshafen, Germany)

- Huntsman Corporation (Texas, U.S.)

- Sinopec Group (Beijing, China)

- Lubrizol Corporation (Ohio, U.S.)

- Kraton Corporation (Texas, U.S.)

- Tosoh Corporation (Tokyo, Japan)

- Other Key Players

Applications Driving Demand

- Automotive Industry – The largest application segment for TPEs. Automakers are increasingly using TPEs for interior trims, instrument panels, seals, and under-the-hood components. These materials not only reduce vehicle weight, which improves fuel efficiency, but also enhance comfort and aesthetics.

- Medical Sector – TPEs are widely used in medical tubing, seals, syringe plungers, and various device housings due to their biocompatibility and sterilization capabilities. The demand for medical-grade TPEs surged during the COVID-19 pandemic, and this segment continues to see growth due to rising healthcare needs.

- Construction Industry – TPEs are used in roofing membranes, seals, and weatherproofing applications thanks to their flexibility and resistance to harsh environmental conditions.

- Footwear Industry – The flexibility, cushioning, and durability of TPEs make them ideal for shoe soles and sports footwear.

- Electronics and Electrical Applications – TPEs are used for cable insulation, connectors, and various protective casings because of their excellent electrical insulation properties and resistance to heat and chemicals.

Read More : https://www.fortunebusinessinsights.com/thermoplastic-elastomer-tpe-market-104515

Key Market Trends

- Shift Toward Bio-based and Recyclable Materials – Growing environmental awareness and stricter regulations are pushing manufacturers to develop bio-based and fully recyclable TPE products.

- Technological Innovations – Advances in polymer chemistry are leading to improved performance characteristics, making TPEs suitable for more demanding applications.

- Lightweighting in Transportation – As the automotive and aerospace industries strive for greater fuel efficiency, lightweight materials like TPEs are gaining more importance.

- Medical-Grade TPE Development – The healthcare industry is demanding materials that are safe, compliant with global regulations, and suitable for repeated sterilization, leading to innovation in medical-grade TPEs.

Regional Insights

- Asia Pacific is the leading regional market for TPE, accounting for over half of the global share in recent years. Countries like China, India, Japan, and South Korea have robust manufacturing bases, particularly in automotive, footwear, electronics, and industrial products. Rapid urbanization, growing infrastructure projects, and increasing disposable incomes in these countries continue to drive demand for TPE products.

- North America is another significant market, with the United States playing a central role due to its advanced automotive and medical sectors. The region is seeing steady growth, supported by consumer demand for high-performance and sustainable products.

- Europe, led by Germany, France, Italy, and the UK, is focusing on lightweighting in vehicles, environmental compliance, and energy efficiency, all of which favor increased use of TPEs. Meanwhile, emerging markets in Latin America, the Middle East, and Africa are projected to see gradual but consistent growth, spurred by industrial expansion and rising consumer goods manufacturing.

Key Industry Developments:

- August 2020: Lubrizol invested in the thermoplastic polyurethane business globally. The investments include the increased production capabilities of surface paint protection film (PPF) and protection. At the same time, it would provide additional benefits to PPF manufacturers and supply chains.

- November 2020: Evonik announced the cooperation with HP for developing a new co-branded1 elastomer, a flexible high-performance specialty powder based on a thermoplastic amide grade (TPA) for 3D printing.

Challenges in the Market

Despite the strong growth outlook, the TPE market faces certain challenges. Volatility in raw material prices, particularly those derived from petroleum, can affect production costs. In addition, competition from alternative materials, such as cheaper plastics or thermoset rubbers, can slow adoption in cost-sensitive markets. Recycling, while possible with TPEs, is still not widely implemented in many regions, limiting the full realization of their sustainability potential.

Leading Industry Players

Major companies operating in the global TPE market include Arkema SA, BASF SE, Covestro AG, Evonik Industries, Huntsman Corporation, Kraton Corporation, Sinopec, Lubrizol Corporation, Teknor Apex, and Tosoh Corporation. These companies are investing heavily in research and development to create advanced, sustainable TPE products, expand production capacity, and strengthen their market positions through strategic partnerships and acquisitions.

Future Outlook

The future of the TPE market looks promising. Growing environmental regulations, increased focus on recyclability, and the need for high-performance materials will continue to push demand upward. As more industries embrace sustainable manufacturing practices, the role of TPEs will expand, particularly in automotive, healthcare, and electronics sectors.

With ongoing innovations, expanding applications, and strong growth in emerging markets, the TPE industry is set to remain a dynamic and competitive sector over the coming decade. Manufacturers that can balance cost, performance, and sustainability are likely to capture the largest share of the market’s future growth.