3D Printing Materials Market Demand, Drivers & Global Growth, Forecast 2032

The global 3D printing materials market was valued at USD 1.53 billion in 2018 and is expected to expand to USD 3.78 billion by 2026, registering a CAGR of 12.1% during the forecast period. North America led the market in 2018 with a 37.91% share, while the U.S. market alone is projected to reach USD 1.28 billion by 2026, fueled by the rising adoption of additive manufacturing across diverse industries.

Market Dynamics

3D printing materials market are essential for producing prototypes, functional parts, and end-use products using additive manufacturing technologies. These materials include plastics, metals, ceramics, and composites, each serving unique applications. The growing preference for lightweight, durable, and cost-efficient materials is reshaping production in industries ranging from aerospace and automotive to healthcare and consumer electronics.

One of the key factors propelling the market is the increased demand for rapid prototyping and mass customization. Companies are increasingly using 3D printing to shorten product development cycles, reduce costs, and achieve greater design flexibility. Another major driver is the reduced material waste associated with additive manufacturing compared to conventional production, aligning with the global push towards sustainability.

However, challenges remain. The cost of 3D printing materials market is significantly higher than traditional manufacturing inputs, often 10–15 times more expensive. Additionally, the market is fragmented with only a limited number of dominant vendors, leading to intense competition and price pressures. These challenges, while notable, are expected to be mitigated by ongoing research, innovation, and the entry of new suppliers.

List of Top 3D Printing Materials Companies:

- Stratasys Ltd.

- 3D Systems, Inc.

- Materialise NV

- Markforged, Inc.

- EOS GmbH

- Höganäs AB

- Arkema

- Royal DSM N.V.

- ExOne

- GE Additive

- Evonik Industries AG

- Höganäs AB

- BASF SE

- Covestro AG

Growth Drivers

Several key trends are fueling the expansion of the 3D printing materials market:

- Rising adoption in aerospace and defense: Demand for lightweight, durable, and fuel-efficient components is accelerating material usage.

- Healthcare applications: The production of implants, prosthetics, and dental devices is boosting demand for biocompatible and specialty materials.

- Sustainability focus: Additive manufacturing reduces material waste, aligning with environmental goals and sustainable production.

- Advancements in material science: Ongoing R&D is leading to the development of stronger, more versatile, and cost-efficient 3D printing materials.

Material Insights

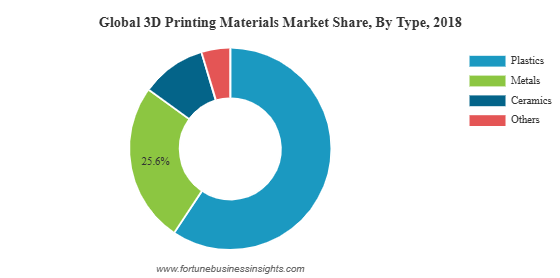

Among the different material types, plastics hold the largest market share. Their affordability, versatility, and widespread use in prototyping make them the preferred choice for industries such as consumer goods and electronics. Thermoplastics like PLA, ABS, and nylon dominate the segment due to their ease of processing and compatibility with multiple 3D printing technologies.

On the other hand, the metal segment is registering the fastest growth. Industries such as aerospace, automotive, and healthcare are increasingly turning to metal-based 3D printing for high-performance applications. The ability to produce complex, lightweight, and durable components has made metals like titanium, aluminum, and stainless steel critical in these sectors.

Ceramics and composites also play a niche but growing role. Ceramics are being explored for high-temperature and biomedical applications, while composites enhance mechanical properties by combining polymers with reinforcing materials like carbon fibers. Photopolymers are another important category, particularly in dental and medical applications, due to their precision and biocompatibility.

Read More : https://www.fortunebusinessinsights.com/3d-printing-material-market-102296

Application Landscape

The application of 3D printing materials market spans multiple industries. The aerospace and defense sector is one of the largest consumers, leveraging additive manufacturing to create lightweight parts, reduce fuel consumption, and enhance performance. The automotive industry uses 3D printing for prototyping, tool manufacturing, and increasingly for producing functional components.

In the healthcare sector, demand is surging for biocompatible materials that enable the production of implants, prosthetics, and surgical models. Customized solutions and patient-specific products are becoming mainstream, offering significant improvements in medical care. The industrial manufacturing sector also benefits from 3D printing, particularly in producing tools, jigs, fixtures, and replacement parts on demand.

Regional Highlights

North America dominated the market in 2018, capturing nearly 37.91% of the global share. The region’s strong growth is attributed to technological advancements, widespread adoption of 3D printing, and investments from major aerospace and automotive players. The United States remains a leader in the market, with projections estimating a value of over USD 1.2 billion by 2026.

Meanwhile, Asia-Pacific is emerging as the fastest-growing region. The surge is driven by rapid industrialization, the growth of consumer electronics, and government initiatives promoting advanced manufacturing. Countries like China, Japan, South Korea, and India are witnessing increasing adoption of 3D printing across automotive, healthcare, and industrial sectors. Europe also maintains a strong position, particularly in Germany, which has become a hub for additive manufacturing innovation.

Key Industry Developments:

- September 2019 – 3D Systems launched new materials for 3D printing namely PRO-BLK 10, and HI-TEMP 300-AMB. The new products will diversify the company’s product portfolio and expand the range of applications for customers.

- November 2018 – Royal DSM N.V. launched “Arnitel ID2060 HT”, a high-performance thermoplastic copolyester for 3D printing by using fused filament fabrication. The filament offers a balance of properties such as chemical resistance, flexibility, and high-temperature resistance.

Challenges

Despite its immense potential, the market faces hurdles. High material costs remain a significant barrier to widespread adoption, particularly for small and medium-sized enterprises. Additionally, the lack of standardized processes and certifications in some industries slows down broader application. Supply chain limitations and the need for advanced technical expertise also pose challenges.

Future Outlook

The outlook for the 3D printing materials market remains highly promising. With an expected CAGR of over 12% through 2026, opportunities abound for manufacturers, suppliers, and end-users. The continuous development of innovative materials, coupled with expanding applications across industries, will play a central role in driving growth.

As companies increasingly prioritize sustainability, customization, and efficiency, the demand for advanced 3D printing materials will continue to rise. The aerospace, automotive, and healthcare industries will remain the largest contributors, while emerging sectors like construction and consumer goods add new growth avenues.

The 3D printing materials market is on the cusp of significant transformation. From plastics to metals and beyond, these materials are reshaping the way industries design, prototype, and manufacture products. While challenges like high costs and market fragmentation persist, the overall growth trajectory is strong, fueled by innovation and the expanding adoption of additive manufacturing worldwide. By 2026, the market is set to nearly double in size, reflecting the profound impact of 3D printing on global manufacturing.