Protective Packaging Market Share, Size, Industry Analysis & Forecast 2030

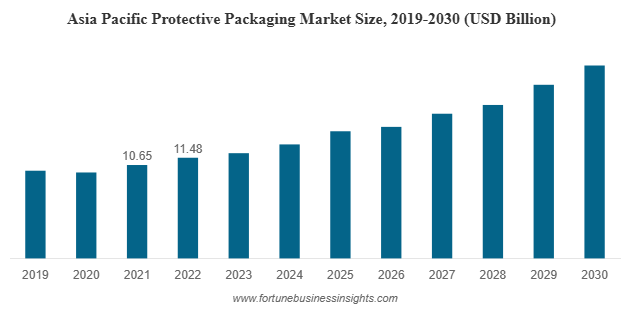

The global protective packaging market was valued at USD 36.31 billion in 2022 and is expected to expand from USD 38.52 billion in 2023 to USD 61.44 billion by 2030, reflecting a compound annual growth rate (CAGR) of 6.90% during the forecast period. In 2022, the Asia Pacific region led the market, accounting for 31.62% of the global share. Meanwhile, the U.S. protective packaging market is also anticipated to witness strong growth, with projections estimating it will reach USD 14.80 billion by 2032. This growth is largely driven by the rising demand for protective packaging in international trade activities.

In an era dominated by online shopping, global logistics, and heightened consumer expectations, protective packaging has emerged as one of the most critical components in product delivery. From fragile electronics to perishable foods, protective packaging ensures that goods reach customers safely and in top condition.

List Of Key Companies Profiled In Protective Packaging Market:

- Smurfit Kappa (Ireland)

- Westrock Company (U.S.)

- Sealed Air Corporation (U.S.)

- Sonoco Product Company (U.S.)

- Huhtamaki (Finland)

- DS Smith PLC (U.K.)

- Pregis LLC (U.S.)

- Pro-Pac Packaging Limited (Australia)

- Storopack (Germany)

- Intertape Polymer Group (U.S.)

Growth Drivers

- The E-Commerce Explosion

E-commerce has reshaped the way we shop. With products shipped directly to doorsteps, the demand for protective packaging has surged. Customers now expect their orders to arrive in pristine condition—whether it's a smartphone, skincare product, or a frozen meal. Packaging that fails to protect leads to returns, dissatisfaction, and brand damage. As online shopping becomes the default, businesses are investing heavily in durable, lightweight, and cost-effective packaging solutions.

- Expanding Applications Across Industries

Protective packaging market is no longer confined to just electronics or fragile goods. It’s now an essential requirement in industries such as:

- Food and Beverage: Ensures freshness and prevents contamination during transport.

- Pharmaceuticals: Maintains the integrity and safety of sensitive medical products.

- Automotive and Electronics: Shields against mechanical damage, moisture, and dust.

- Cosmetics and Personal Care: Protects aesthetic packaging and preserves shelf appeal.

The more industries that rely on long-distance shipping, the more critical packaging becomes to business operations.

- Rising Demand in Developing Regions

Asia-Pacific currently holds the largest market share and continues to be the fastest-growing region. Countries like China and India are experiencing massive e-commerce growth, expanding manufacturing bases, and urbanization—all of which contribute to increased demand for protective packaging. Additionally, Latin America and the Middle East & Africa are witnessing steady growth as global trade increases and consumer purchasing power rises.

Trends Shaping the Market

- Sustainable Packaging Solutions

Plastic continues to dominate the market due to its low cost, durability, and efficiency. However, growing environmental concerns are pushing both companies and consumers toward greener alternatives. There is a strong trend toward the use of recyclable materials, biodegradable films, and molded pulp packaging. Businesses are under pressure to strike a balance between functionality and sustainability—without sacrificing protection.

- Growth in Flexible and Wrapping Packaging

Among the various product types, flexible packaging solutions are seeing the fastest growth. These include bubble wrap, paper wraps, and foam-in-place solutions, which offer excellent cushioning while being adaptable to various product sizes and shapes. Wrapping packaging is especially popular for its lightweight nature, ease of customization, and cost efficiency. These solutions are essential for reducing shipping weight and protecting irregularly shaped items.

- Advanced Protective Functions

Today’s protective packaging does more than just prevent breakage. Key functions include:

- Void Fill: Prevents products from moving during transit.

- Cushioning: Absorbs shock and vibration.

- Insulation: Maintains product temperature (especially in food and pharma sectors).

- Blocking and Bracing: Secures products in place inside the container.

These multifunctional aspects of protective packaging are becoming essential for meeting increasingly complex logistical requirements.

Read More : https://www.fortunebusinessinsights.com/protective-packaging-market-107319

What Businesses Should Focus On

For companies that manufacture, ship, or sell physical products, the rise of the protective packaging market presents both a challenge and an opportunity. Here are a few key takeaways:

- Invest in R&D: Stay ahead by developing or using sustainable and advanced packaging materials.

- Optimize Packaging Design: Go beyond protection—design for space efficiency, brand identity, and user experience.

- Partner Strategically: Work with reliable suppliers who offer innovative, compliant, and cost-effective packaging solutions.

- Educate Consumers: Highlight your sustainable packaging efforts as part of your brand story. Today’s consumers care.

Key Industry Developments:

- August 2023 – Ranpack launched Wrap’n Go converter for protective honeycomb paper. The company brought its Geami Wrap’n Go converter, which turns kraft paper into protective, pack-in-store packaging for fragile items, to the North American market, providing an alternate option to the plastic solution.

- February 2023 – The circular materials company Cruz Foam announced the launch of a revolutionary new product family of environmentally protective packaging, introducing highly efficient solutions that meet the specific needs of customers in transporting sensitive and temperature-sensitive goods to consumers and businesses.

Challenges and Opportunities

- Regulation and Compliance

Governments worldwide are enacting stricter regulations on single-use plastics and non-recyclable materials. As sustainability becomes non-negotiable, packaging manufacturers are investing in R&D to develop eco-friendly solutions that comply with international standards. This opens doors for innovation and differentiation in the market.

- Supply Chain Resilience

The COVID-19 pandemic exposed the fragility of global supply chains. Delays in raw materials and disruptions in manufacturing highlighted the need for more robust and localized packaging solutions. Companies are now diversifying their supplier base and investing in supply chain resilience to avoid future setbacks.

- Technological Innovation

Technological advancements such as smart packaging (which can monitor temperature and tampering), automation in packaging lines, and the integration of AI for packaging design are becoming game-changers. These innovations not only improve efficiency but also reduce waste and costs in the long run.

Outlook

Protective packaging market is no longer just a backend logistics concern—it’s a strategic asset. With the market set to nearly double over the next decade, businesses that prioritize innovation, sustainability, and adaptability in their packaging strategies will be better positioned to thrive in an increasingly competitive landscape.

From cushioning to compliance, the future of protective packaging is dynamic, and it’s reshaping how products are shipped, received, and experienced around the world.